A new method for 3D printing materials that resemble the strength and flexibility of human flesh has been developed by researchers.

The University of Pennsylvania and the University of Colorado Boulder collaborated to create this novel 3D printing technique, which is known as continuous curing after Light Exposure Aided by Redox initiation (CLEAR).

It's interesting to note that this method will provide materials with a special mix of qualities: toughness to withstand joint pressure, flexibility to withstand the continuous pounding of the heart, and adaptability to meet individual patient needs.

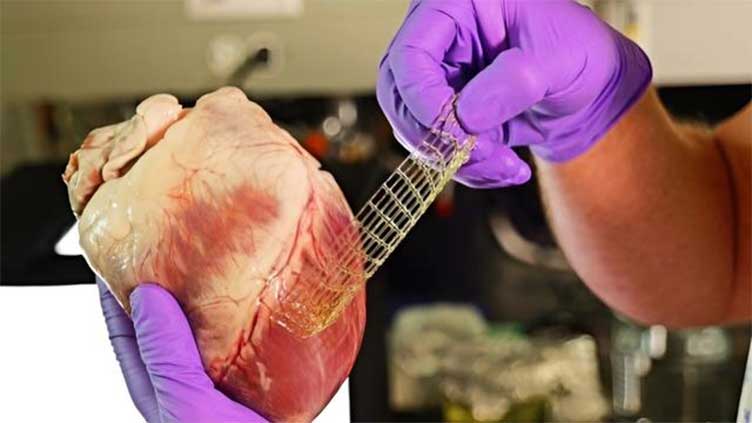

The group anticipates that this method will lead to the development of sophisticated biomaterials including cartilage patches, drug-infused cardiac dressings, and sutureless materials.

Similar to cartilage, cardiac tissues have a very limited capacity for self-healing. Once they are harmed, there's no recovery. We can significantly improve patient outcomes by creating new, more resilient materials to facilitate the mending process, according to senior author Jason Burdick.

3D printers use various materials, including living cells, to produce objects layer by layer. Although ordinary 3D-printed hydrogels may lack the strength and flexibility needed for medical purposes, hydrogels are widely used to create artificial tissues.

Consider what would happen if your heart were covered in hard plastic. It wouldn't sag with each heartbeat. It would simply break apart," Burdick remarked.

However, this new 3D method creates strong, flexible polymers that might attach to wet tissue. By entwining lengthy molecules in 3D-printed materials, CLEAR functions. Worms' complex entanglement served as the inspiration for this concept.

The recently developed materials underwent extensive stretching and weight-bearing testing, which included an odd technique where a bicycle was driven over the sample.

They discovered that the materials were far more durable than those made with a typical 3D printing procedure. These polymers also impressively showed adherence and compatibility with animal tissues and organs.

Adhesive compounds strong enough to mechanically support tissue can now be 3D printed. Matt Davidson, a research associate in the Burdick Lab and co-first author, stated, "We have never been able to do that before."

In the future, Burdick and colleagues hope to use these 3D-printed materials to treat heart abnormalities, brace herniated discs, deliver tissue-healing medications directly to organs, and conduct sutureless surgical closure.

Furthermore, because it avoids the energy-intensive hardening step that is normally necessary for 3D printing, this method is environmentally benign.

According to the press release, first author and Burdick Lab researcher Abhishek Dhand stated, "This is a simple 3D processing method that people could ultimately use in their academic labs as well as in industry to improve the mechanical properties of materials for a wide variety of applications."

The team has submitted a preliminary patent application and plans to carry out additional studies to investigate the materials' effects on tissue.

The journal Science published a report on the findings.